Glossary - What is HexShell, Duratex, and TPU? What is EvoBeam and Dropstitch?

Here at Aquaglide, we use a variety of materials to build all of our paddlesports products. These materials and floor constructions have different qualities and characteristics, and understanding the differences is instrumental in helping you decide which craft is right for you.

Boat Materials

HexShell Material – HexShell is a robust 600 denier hexagonal ripstop polyester fabric, with a durable UV resistant and water repellant treatment. We use this material as an integrated cover, supporting separate welded air bladders made of PVC. The combined covered bladder assembly makes a strong, capable craft, with excellent recreational performance, value and durability. This modular style of construction means that various parts of the boat can be easily replaced if necessary. Bladders can shift inside of cover, occasionally requiring adjustment, and repair of leaks generally requires bladders to be temporarily removed from boat.

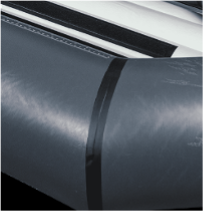

Duratex – We use ‘Duratex’ to describe our proprietary formulation of fabric-reinforced PVC. Variations of this material, also known as PVC tarpaulin, are widely used in whitewater rafts, RIB tender boats, tents and awnings. At its core is a layer of 1000 denier (1100 Decitex) polyester fabric which is coated with molten PVC under great heat and pressure to create a tough, stable, air-holding material which is stiff enough to provide excellent on-water performance, durable enough to ensure extensive product life, and supple enough to facilitate efficient folding/packing. Depending on its use, Duratex material can be considered heavy or moderate in weight, but not typically ‘ultralight’. Although more expensive than Hexshell construction, Duratex does not require any adjustment as bladder and shell are combined in a single fabric.

TPU – TPU stands for Thermoplastic Polyurethane. We utilize various thin TPU films laminated to tough, tenacious 210 denier nylon fabric on one or both sides to create an ultralight, ultra-tough, air holding material. We’re excited about TPU/ Nylon for its outstanding performance, but also because if its reduced impact on the environment. TPU is more sustainable than PVC, plus it’s outstanding abrasion-resistance means we’re using 1/10th the material weight to achieve similar performance to Duratex. While TPU has many clear advantages, high demand for this material means that it comes at a premium. In the lighter weight specifications we apply for TPU, it may not be quite as durable as Duratex material.

Floor Construction

EvoBeam – EvoBeam is our redesign on the classic beam construction used to create a flat or slab-shaped inflatable structure, like a kayak floor. We utilize specially formulated, quality materials, double-sided tabs, tight circular beam ends, and infinite beams wherever possible. AG EvoBeam has been proven with thousands of satisfied kayakers since the release of this technology in 2020. While the primary advantage of EvoBeam construction may be its economic value, this construction also allows for subtle bottom shaping for improved tracking and vee shape. One disadvantage for performance users is that this construction tends to be more flexible than (significantly more expensive) high pressure dropstitch.

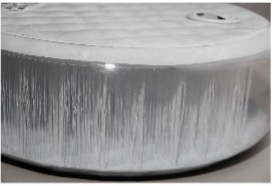

PVC Dropstitch – Dropstitch is made using thousands of equally-spaced polyester fibers or ‘stitches’ sewn between top and bottom layers of polyester fabric. The layers are then treated with molten PVC under great heat and pressure to form an extremely robust air-holding chamber. We use high-pressure, single-layer PVC dropstitch in 8 cm thickness to provide rigid floors for our performance inflatable boats, and thicker 12cm+ material for inflatable SUPs. Dropstitch can hold much higher air pressure than classic beam or even EvoBeam construction which means better stiffness, improved stability and improved energy transfer. The only disadvantage with dropstitch is that this complex technology comes at a premium cost.

PVC Dropstitch comes in a number of variations, starting with Single-layer (described above). More technical variations, such as Double-layer PVC Dropstitch involve laminating an additional layer of reinforced PVC (ie. Duratex) either by hand-gluing or by machine lamination for improved stiffness and airholding.

Fused Structural Laminate (FSL) Dropstitch – Like other dropstitch technologies, FSL dropstitch begins with thousands of equally-spaced polyester fibersor ‘stitches’ sewnbetween top and bottom layers of polyester fabric. Next, layers of PVC tarpaulin (see Duratex) are fused directly to the dropstitch core fabrics during manufacturing with extreme heat and pressure. The end-product is light weight, stiff and has excellent air-holding ability. This manufacturing process produces material comparable to a ‘Monocoque Structural Laminate’. So much so that the end user is unlikely to discern the difference. This technology saves unnecessary weight by eliminating the hot-knife coating of Single Layer dropstitch, and also the thick, hand-laminated glue of Double Layer dropstitch construction. Widely acknowledged as the optimal material for inflatable SUPs, FSL dropstitch carries a cost premium.